SAEKI, a manufacturing company founded by ETH Zurich graduates, has secured $6.7 million in seed funding to address challenges in large-scale manufacturing. Global industries like aerospace and automotive currently face slow production times and high costs for large components. SAEKI aims to solve these issues with a new approach to 3D-printing and manufacturing.

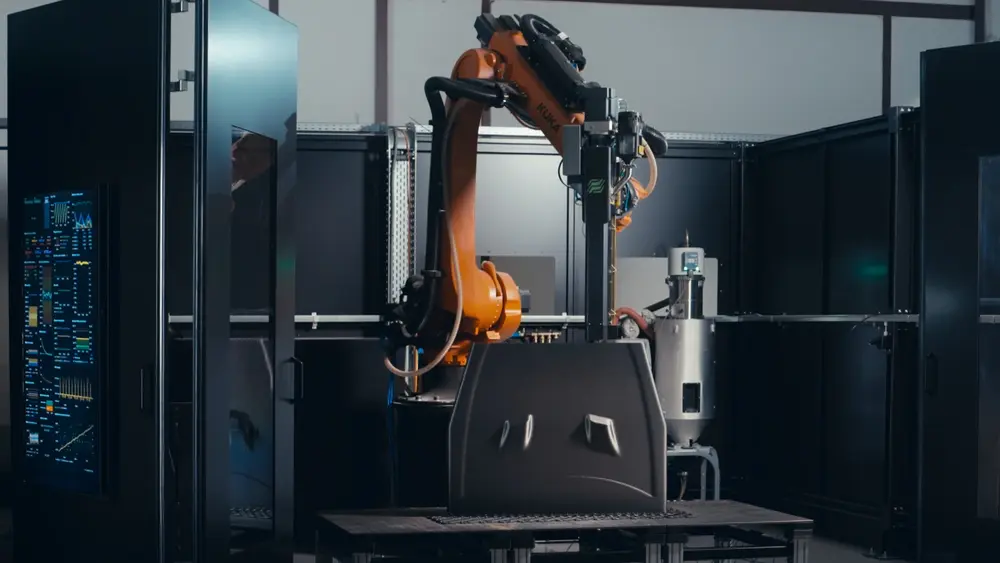

SAEKI uses a combined manufacturing system that integrates large-scale 3D printing with precise CNC machining. This hybrid method allows them to produce custom, engineered parts faster and with high accuracy. They also use automated quality checks to ensure parts meet industry standards. Additionally, SAEKI has launched an online platform that provides instant price quotes to customers who upload their designs, speeding up the ordering process.

"Our goal at SAEKI is to make manufacturing faster, more efficient, and more reliable," says Andrea Perissinotto, co-founder and CEO. "We are automating the entire process, from getting a quote to final inspection, so that advanced designs can be manufactured at scale."

Current manufacturing processes for large components are often slow, expensive, and rely on manual work. This creates a gap between advanced engineering designs and the ability to actually manufacture them efficiently. SAEKI’s approach helps to close this gap by streamlining production and reducing lead times.

"SAEKI's ability to deliver high-quality components quickly and reliably is setting a new standard for the manufacturing industry," noted Thomas Meier, Partner at Lightbird.

The seed round was led by Lightbird with participation from Founderful, 2100VC, Danobat, and multiple high-profile business angels. The new funding will be used to accelerate SAEKI's development of fully automated factories. These factories will integrate quoting, 3D printing, machining, and quality inspection into one continuous system.

SAEKI's technology aims to improve manufacturing efficiency, reduce waste, and strengthen European manufacturing capabilities. By combining advanced technologies and automation, SAEKI is working to make manufacturing faster and more accessible for industries needing large, precision components.